DENSITY SEPARATION SOLUTIONS

For high purity and high germanation

Density separators also called gravity separators, divide heavier particles of material from lighter particles differing in their specific densities. While they are often used for seed and grain operations, gravity separators have a variety of applications. Gravity separators can be used to separate coffee, nuts, food, and other dry bulk material. The process of fluidization allows the gravities to separate both light and heavy contaminants from a product simultaneously.

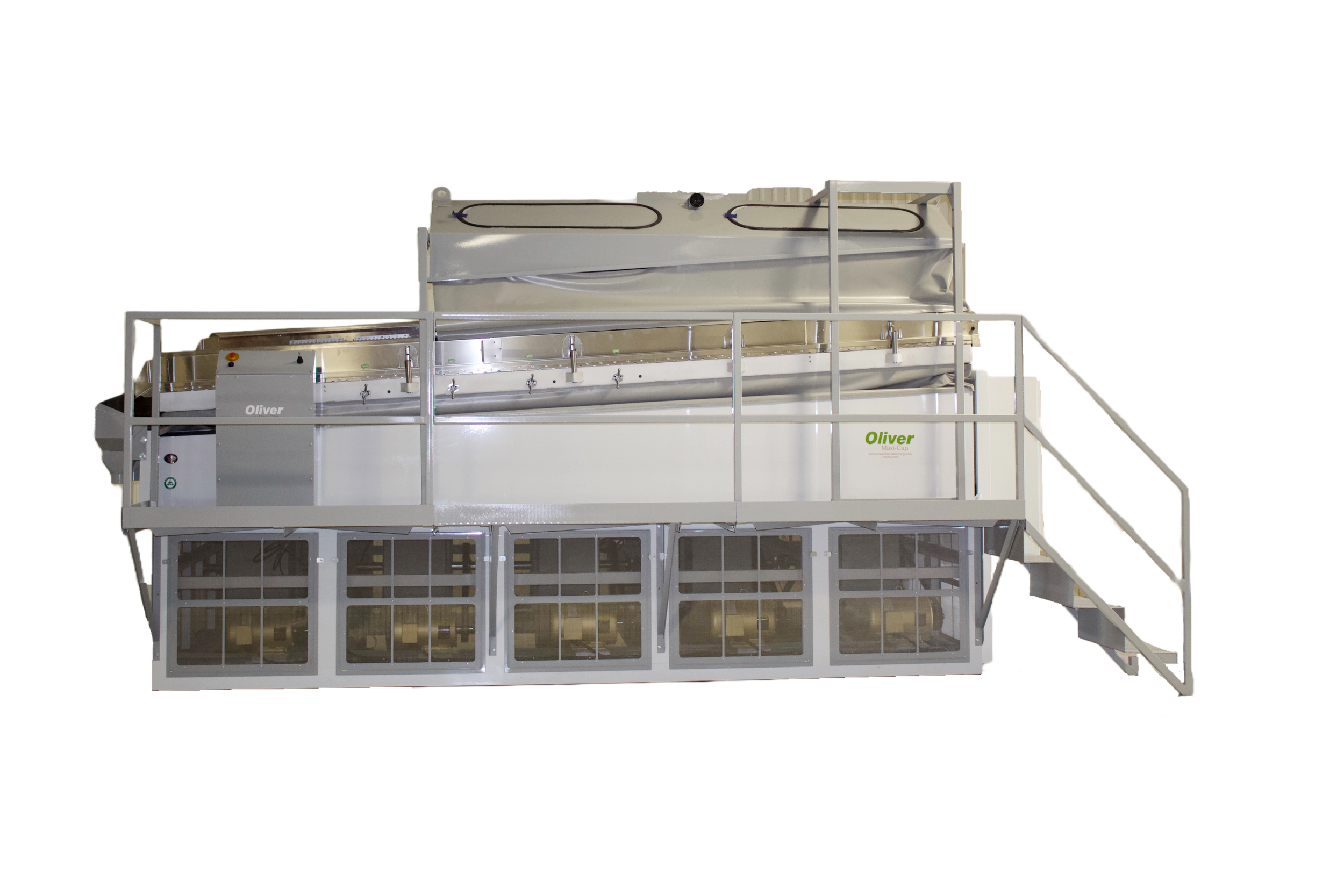

One of the most advanced high-capacity separators on the market, the Maxi Cap Platinum adds one-touch power electronic control and repeatable memory. Capacity up to 13.9-19.5 t/h.

Models: 3600P, 4800P

The Maxi-Cap gravity table removes heavier stone, glass, metal and sands as well as lighter lumber or agriculture products or plastics. Precise hydraulics and Opti-Drive automation make adjustment during operation a snap. Aspirating feeder removes the lightest contaminants as product is being introduced. Capacity 10-13.6 t/h.

Models: 3600, 4800

Programmable Logic Circuitry with a pre-loaded menu of up to 20 separation “recipes” means faster and simpler changeover between different products, and optimal separations from even the most minimally-trained operator no matter what your density separation, size separation or contaminant removal needs. Capacity 3.2-6.8 t/h.

Models: GVX 1020, GVX 1040, GVX 1050

The Hi-Cap series separates continuous flow of granular products. Multiple fan zones allow for efficient control of product flow. Decks are designed and built to optimally perform for your specific product. Capacity 0.2-6.5 t/h.

Models: HC 51, HC 81, HC 161, HC 241

Density Separation

-

Density separation is used for fine grading and removal of impurities with identical particle size but with differences in density. Our gravity separators have a highly efficient air intake with a built-in fan ensuring a uniform air distribution across the entire deck.

-

A density separate has a vibrating deck with air flow. The angle of the deck can be adjusted in two directions, combined with the speed of deck oscillation, and the adjustable airflow, this allows for the product to be separate into different fractions by density.

-

If You will have a high purity and high germination.